-

Type 90 Minutes Safety Storage Cabinets FLAB9120

1. Doors lockable with cylinder lock

2. Integrated air ducts ready for connection (DN 75) to a technical exhaust system can be used for the extraction of hazardous substances vapours

3. Extremely robust design with scratch-proof surface

4. Door lockable with cylinder lock, the cabinets can be integrated by the customer into an existing locking system

5. Doors stay in place at any opening angle for a more convenient handling of containers

6. Integrated transport base for simple inhouse transport, cabinet can be transported upright through doors -

Safety Showers and Eyewash SS3011

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

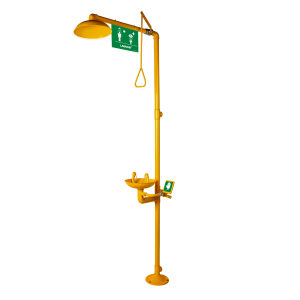

Emergency Showers and Eyewash with Epoxy SS3001Y

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

Safety Showers and Eyewash SS3001

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

Memmert ICH260C Climate Chamber [Resale]

*Additional charge for installation

*One Science does not handle the warranty for resale items

Setting temperature range: -10 to +60 °C

Working temperature range: from -10°C up to +60°C without humidity (not suitable for long-term storing at sub-zero temperatures. During permanent operation, the glass door may ice over)

Working temperature range: from +10°C up to +60°C with humidity and/or light

Setting accuracy temperature: 0.1 °C

Temperature sensor: 2 Pt100 sensors DIN Class A in 4-wire-circuit for mutual monitoring, taking over functions in case of an error

Works calibration certificate: standard values +10 °C and +37 °C, 60 % rh at +30 °C

Door: inner glass doors

Door: fully insulated stainless steel doors with 2-point locking (compression door lock)

Entry port: Entry port (silicone), 40 mm clear diameter, moisture tight, can be closed by a silicone stopper, standard position at the back

Humidity: humidity supply with distilled water from external tank by self-priming pump

Humidification: humidification by hot steam generator

Humidity: active humidifying and de-humidifying adjustable from 10-80 % rh with digital display of relative humidity – resolution of display 0.1 %, setting accuracy 0.5 %

Fan: forced air circulation

External Dimensions: w(D) x h(E) x d(F): 824 x 1552 x 685 mm (d +56mm door handle)

Internal Dimensions: w(A) x h(B) x d(C): 640 x 800 x 500 mm (d less 33 mm for fan)

Volume: 256 l

Max. number of internals: 9

Max. loading of chamber: 200 kg

Max. loading per internal: 20 kg