-

Type 90 Minutes Safety Storage Cabinets FLAB9120

1. Doors lockable with cylinder lock

2. Integrated air ducts ready for connection (DN 75) to a technical exhaust system can be used for the extraction of hazardous substances vapours

3. Extremely robust design with scratch-proof surface

4. Door lockable with cylinder lock, the cabinets can be integrated by the customer into an existing locking system

5. Doors stay in place at any opening angle for a more convenient handling of containers

6. Integrated transport base for simple inhouse transport, cabinet can be transported upright through doors -

Safety Showers and Eyewash SS3011

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

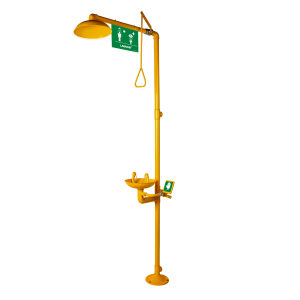

Emergency Showers and Eyewash with Epoxy SS3001Y

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

Safety Showers and Eyewash SS3001

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

FD-10P Bench Top Freeze Dryer

Standard stopper with 8 port manifolds

Package includes:

- Vacuum freeze dryer host 1 set

- Drying rack 1pc

- Material tray 4 pc

- Pre-freezing rack 1 pc

- PC cover 1pc

- Vacuum pump 1 pc

- Vacuum pump connection pipe 1pc

- Vacuum pump oil 1 pc

- Connection clamp (including sealing ring) 2 pcs

- Manual and certificate 1 pc

- Power cord 1 pc

- Vacuum silicone grease 1 pc

- Tee component 8 pcs

- Lyophilized bottle 8 pcs (800ml/pc)

Freeze dryer is widely applied in pharmaceutical industry, biotechnology industry, biological science industry, materials science industry, chemical industry, food and agriculture industry etc. It is used to produce vaccines, drugs and permanently store biological tissues/organs.

-

FSF-040S 10L Ultrasonic cleaner with heater and timer

Features:

- Use ordinary tap water, alcohol or solvent as cleaning;

- High power transducer cleaning effect significantly; usable macroscopic observation;

- After cleaning objects shine light;

- Digital LCD control boot time;

- The stainless steel shell, bladder and cover, more upscale;

- Waterproof properties is greatly improved,more safely products last;

- With constant temperature system with heating;

- The stainless steel ultrasonic cleaning basket (optional).