-

Type 90 Minutes Safety Storage Cabinets FLAB9120

1. Doors lockable with cylinder lock

2. Integrated air ducts ready for connection (DN 75) to a technical exhaust system can be used for the extraction of hazardous substances vapours

3. Extremely robust design with scratch-proof surface

4. Door lockable with cylinder lock, the cabinets can be integrated by the customer into an existing locking system

5. Doors stay in place at any opening angle for a more convenient handling of containers

6. Integrated transport base for simple inhouse transport, cabinet can be transported upright through doors -

Safety Showers and Eyewash SS3011

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

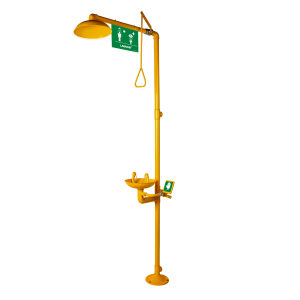

Emergency Showers and Eyewash with Epoxy SS3001Y

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

Safety Showers and Eyewash SS3001

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

SILICONE 3D PRINTER (UNIT)

SanDraw is a 3D printer manufacturer founded in 2014 in Silicon Valley, USA.

Sandraw’s patented fluid additive manufacturing (FAM) technology specialises in 3D printing of two-part silicone, one-part silicone, and various gel-like third-party materials.

FAM is the first commercialised silicone 3D printing technology, with more than 100+ 3D printers sold globally and 500+ printing cases, in both research and industrial sectors.

In 2022, San Draw launched S300 printer, which is the first silicone 3D printer capable of printing water-soluble support material.