-

Type 90 Minutes Safety Storage Cabinets FLAB9120

1. Doors lockable with cylinder lock

2. Integrated air ducts ready for connection (DN 75) to a technical exhaust system can be used for the extraction of hazardous substances vapours

3. Extremely robust design with scratch-proof surface

4. Door lockable with cylinder lock, the cabinets can be integrated by the customer into an existing locking system

5. Doors stay in place at any opening angle for a more convenient handling of containers

6. Integrated transport base for simple inhouse transport, cabinet can be transported upright through doors -

Safety Showers and Eyewash SS3011

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

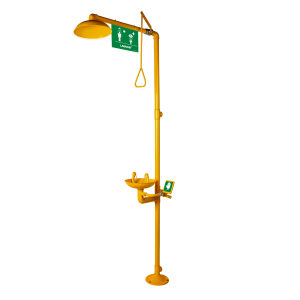

Emergency Showers and Eyewash with Epoxy SS3001Y

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

Safety Showers and Eyewash SS3001

In general, the ANSI standard provides that emergency equipment be installed within 10 seconds walking time from the location of the hazard. The equipment must be installed on the same level as the hazard (i.e. accessing the equipment should not require going up or down stairs or ramps). The path of travel from the hazard to the equipment should be free of obstructions and as straight as possible. Users of the equipment should not have to walk around machinery or other obstacles to reach the unit.

However, there are certain circumstances where these guidelines might not be adequate. For example, where workers are handling particularly strong acids, caustics or other materials where the consequences of a spill would be very serious, emergency equipment should be installed immediately adjacent to the hazard. Laboratory environments also require special consideration. -

BSC-1804IIA2 Biological Safety Cabinet, 6 feet, Class II Type A2

Includes:

•NSF 49 Certification for the 1st year

•UV lamp (1 pc)

•Sockets (2 pcs)

•Valves (2 pcs)

•Adjustable stand

Friendly Control Panel

•Color LED screen, show the air velocity, time, fan station, HEPA filter life and alarm in real time

Safe and Reliable, Energy-Efficient

•DC fan and LED light make the operation power consumption save 30%.

•Intelligent auto-supply system of imported blower ensures the change of air volume less than 10% when the resistance of filter increases 50% and enhance safety.

•The alarm system for safe operation height is interlocked with light. At the same time light is interlocked with sterilizing.

•Leak detection in cabinet, no leakage at 500Pa.

•UV light with set timer, safer and high efficiency.

Humanized design

•10°sloped front make it comfortable to operator.

•Negative pressure and double layers chamber around ensure non-leakage, non-pollution.

•Demountable circular-arc armrest can alleviate working tiredness and make it easy to transport.

•Front window adopts hanging lifting system (Imported from Japan) and more than 5mm thickness security glass with arbitrary positioning, high stability and convenient to sterilization when it closed.

•Front window can be cleaned all-over, solving the problem which front window can’t be cleaned inside

•Moveable working table with handle and support make it easier to clean collecting tank.

•There are two anti-splash spare sockets and four service port in the cabinet.

•Movable stainless steel worktable 4 liter capacity stainless steel collecting tank with below down valve, easy to collect water, cleaning and disinfection.

•Non-obstructive air return mode in the front suction channel .

•The adjustable leveling foot is without exposure thread.

ULPA filters

•USA HV ULPA Filter Medium, provide 99.9995% typical efficiency for particle size over 0.12 microns, and the materials is glass fiber.

• minimum ISO 4 air quality in the work area

•Unique Technology of non leakage

•Every ULPA filters will be tested to ensure non leakage.

ECO mode and power off memory function

•You need not to turn off BSC when stop experiment. You can close front window and BSC will turn to ECO mode to ensure cleanliness in working area. If opening front window, BSC will turn to normal mode immediately.

•If losing power unexpected, BSC will return to the station which before losing power when regain power. This will ensure the safety of operator. -

BSC-1302IIA2 Biological Safety Cabinet 4 feet, Class II Type A2

Includes:

•NSF 49 Certification for the 1st year

•Sockets (2 pcs)

•Valves (2 pcs)

•Detachable stand with adjustable height

Friendly Control Panel

•LED screen, show the air velocity, time, fan station, alarm in real time.

Safe and Reliable, Energy-Efficient

•DC fan and LED light make the operation power consumption save 30%.

•Intelligent auto-supply system of imported blower ensures the change of air volume less than 10% when the resistance of filter increases 50% and enhance safety.

•The alarm system for safe operation height is interlocked with light. At the same time light is interlocked with sterilizing.

•Leak detection in cabinet, no leakage at 500Pa.

•UV light with set timer, safer and high efficiency.

Humanized design

•10°sloped front make it comfortable to operator.

•Negative pressure and double layers chamber around ensure non-leakage, non-pollution.

Demountable circular-arc armrest can alleviate working tiredness and make it easy to transport.

•Front window adopts hanging lifting system (Imported from Japan) and more than 5mm thickness security glass with arbitrary positioning, high stability and convenient to sterilization when it closed.

•Movable stainless steel worktable 4 liter capacity stainless steel collecting tank with below down valve, easy to collect water, cleaning and disinfection.

•Non-obstructive air return mode in the front suction channel.

•The adjustable leveling foot is without exposure thread.

HEPA filters

•USA HV HEPA Filter Medium, provide 99.995% typical efficiency for particle size over 0.3 microns, and the materials is glass fiber.

•A minimum ISO 5 air quality in the work area

•Unique Technology of non leakage.

•Every HEPA filters will be tested to ensure non leakage.